IADC Dull Grading

| Cutting Structure | |||||||

| Inner Rows | Outer Rows | Dull Char. | Location | Bearings/Seals | Gauge | Other Dull Char. | Reason Pulled |

| X | |||||||

|

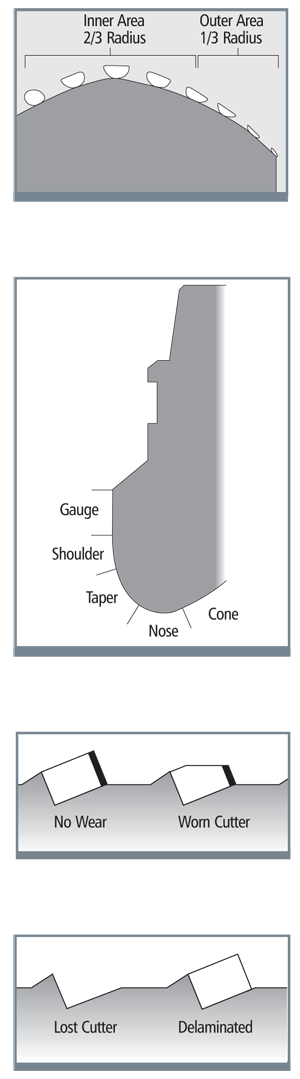

Inner Cutting Structure | X | |||

| Outer Cutting Structure | Gauge | ||||

| A measure of lost, worn and/or broken cutting structure. Linear Scale: 0-8 0 - No lost, worn and/or broken cutting structure 8 - All of cutting structure lost, worn and/or broken |

(Measure in fractions of an inch) I - In Gauge 1 - 1/16" Out of Gauge 2 - 1/8" Out of Gauge 4 - 1/4" Out of Gauge |

||||

| Dull Characteristics | Other Dull Characteristics | ||||

| BF - Bond Failure | (Refer to column 3 codes) | ||||

| BT - Broken Cutters | |||||

| BU - Balled Up | Reason Pulled or Run Terminated | ||||

| CR - Cored | BHA - Change Bottomhole Assembly | ||||

| CT - Chipped Cutters | CM - Condition Mud | ||||

| DL - Delaminated Cutters | CP - Core Point | ||||

| ER - Erosion | DMF - Downhole Motor Failure | ||||

| HC - Heat Checking | DP - Drill Plug | ||||

| JD - Junk Damage | DSF - Drill String Failure | ||||

| LM - Lost Matrix | DST - Drill Stem Test | ||||

| LN - Lost Nozzle | DTF - Downhole Tool Failure | ||||

| LT - Lost Cutters | FM - Formation Change | ||||

| NO - No Dull Characteristics | HP - Hole Problems | ||||

| NR - Not Rerunnable | HR - Hours on Bit | ||||

| PN - Plugged Nozzle/Flow Passage | LIH - Left in Hole | ||||

| RO - Ring Out | LOG - Run Logs | ||||

| RR - Rerunnable | PP - Pump Pressure | ||||

| WO - Washed Out | PR - Penetration Rate | ||||

| WT - Worn Cutters | RIG - Rig Repair | ||||

| TD - Total Depth/Casing Depth | |||||

| Location | TQ - Torque | ||||

| A - All Areas | TW - Twist Off | ||||

| C - Cone | WC - Weather Conditions | ||||

| G - Gauge | WO - Washout - Drill | ||||

| N - Nose | |||||

| S - Shoulder | |||||

| T - Taper | |||||

| API Fixed Cutter Bit Tolerances | |||

| BIT SIZE (IN.) |

FIXED CUTTER BIT O.D. TOLERANCE (IN.) |

FIXED CUTTER BITS - RING GAUGING Any fixed cutter bit should be ring gauged prior to running in the hole. Stabilizers should also be calipered or gauged to verify they meet API-approved outside dimension tolerances as shown in the following table. Fixed cutter bits should not be larger than the nominal diameter. |

|

| 6-3/4 and Smaller | -0.015 to +0.00 | ||

| 6-25/32 to 9 | -0.020 to +0.00 | ||

| 9-1/32 to 13-3/4 | -0.030 to +0.00 | ||

| 13-25/32 to 17-1/2 | -0.045 to +0.00 | ||

| 17-17/32 and Larger | -0.063 to +0.00 | ||

| A “no go” gauge is used to ensure a bit is not smaller than allowed and, as the name implies, it should not go or slip down the entire length of the bit. A “go” gauge ensures a bit is not larger than allowed and should slip down the entire bit. | |||

Technical Data